The truth about asbestos in plaster.

Myth:"Any plaster made before 1981 contains asbestos.

Although the use of asbestos dates back to before the turn of the century (before 1900), United States Gypsum, the largest manufacturer of plaster, did not use asbestos in it's materials until the 1920's.

The before 1981 rule may refer to lead paint, but not asbestos in plaster.

Probably the most hazardous use of asbestos in plaster was the use of asbestos fibers in acoustic plaster that was used widely in the 1950's.

The main use of acoustic plaster was in churches and schools.

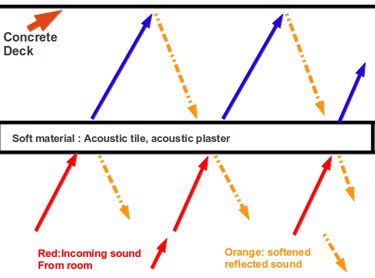

Acoustic plaster was a lightweight, soft plaster for ceilings that was mainly used for noise reduction in areas where people converged, for example church narthexes and hallways in schools.

Acoustic plaster is easily identified by a rough random texture. Usually an acoustic plaster ceiling under 9 feet high has holes poked in it from kids jumping up and hitting the ceiling. This plaster was put on metal lath, usually suspended, and didn't receive any finish coat. It was intentionally very soft.

Sound attenuation is used to soften noise and echos in offices, for example, and areas where people congregate such as church narthexes, hallways in schools, etc. This is the reason for acoustic tile, and lightweight and soft acoustic plaster.

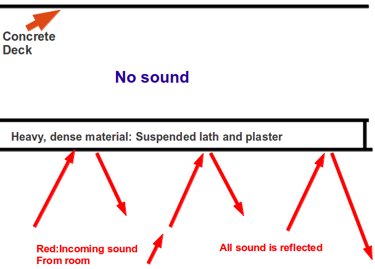

Sound proof is the other extreme. It is used to reflect sound. This is preferred in concert halls, church sanctuaries, auditoriums, recording studios, etc.

The wall is then filled in between the ropes and rodded off with a 6 foot rod.

Acoustic plaster should not be confused with spray acoustic finishes, like you see on motel ceilings, for example. These finishes are a drying type material like drywall compound with plastic or perlite aggregate. The truth is, these materials are referred to as acoustic, but have no sound attenuating properties at all. (Another myth). Spray on acoustic textures, sometimes called popcorn, are probably called acoustic due to the similarity in appearance to acoustic plaster.

Other uses of asbestos in USG's product line was pipe insulation, boiler jackets, early acoustic tiles for ceilings, and roofing materials.

USG also manufactured other asbestos products like cement shingles (often called asbestos shingles), fireproof plaster (for column and metal deck fireproofing) and acoustic plaster. It is unclear how much, if any, asbestos was used in conventional plaster basecoats.

The largest use of asbestos fibers in plaster was for fireproofing, that is for fireproofing metal in commercial builds, and for acoustic plaster.

Before the 1920's, most basecoat plaster in residential use was lime and sand, and not gypsum plaster. It is doubtful that a horse and wagon plasterer would go out of his way to find manufactured asbestos fibers to put in lime plaster.

The reinforcing fibers in lime and sand basecoat plaster was animal hair. Another myth is that this animal hair is horse hair. Even though plaster sometimes contained hair from horses and even humans, most of this hair was from cows and pigs, or animals shaved for leather making. Goat hair was reputedly the best for plaster reinforcement Farmers usually saved up their hair from butchered animals and traded it at the farmers market, where it was sold for plastering use.

Why do I refer to basecoat plaster and not the finish coat plaster ?

The finish coat for plaster was made usually from lime and gauging plaster, or lime and moulding plaster. Fibers in the finish coat would show, so weren't used in the finish coat. Acoustic plaster was just the basecoat left with no finish coat.