Point 10 of my 12 point list of methods for reducing cracking in portland cement stucco

Point 10 -Good lathing

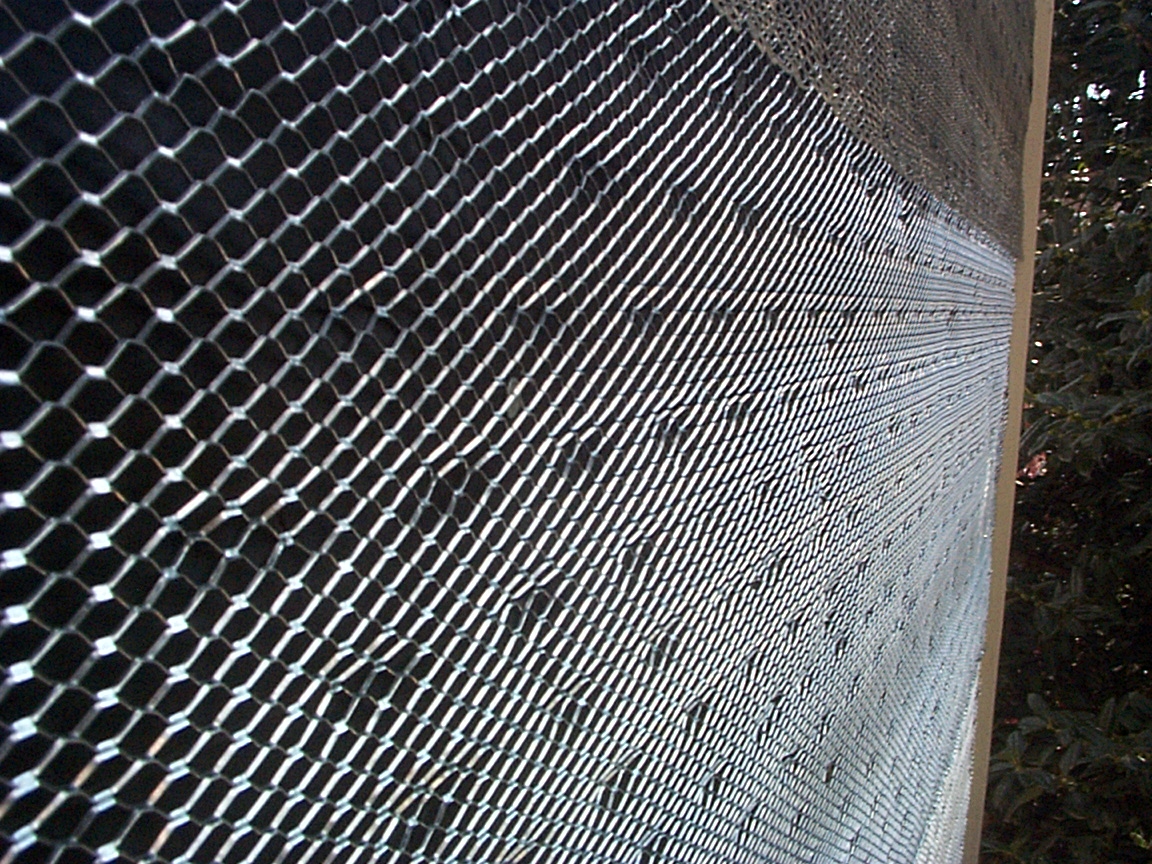

Self Furring Lath

Deep cracks and loose areas caused by bad lathing are impossible to repair, without the repair coming back to haunt.

The reasons for metal lath are:

1. Support (to hold the mortar up)

2. Reinforcement -increased tension strength

Self furring lath has punches 1/4" deep, or "dimples" to hold the lath away from the wall. This allows mortar to penetrate well behind the lath for good support and good embedding of the lath for reinforcement.

I see flat lath used sometimes for stucco. Although the mortar will hang on enough to hold it on, it is still an inadequate method. Out west they use self-furring stucco mesh. Some brands have the punches painted with a dot of yellow or red paint, for easier alignment to the studs. In California they call the diamond mesh lath we use here, "K-lath".

Furring nails were made in the 1920's , and before, for welded wire lath. The nail was a hook that allowed the wire lath to slide down, creating a gap between the lath and the sheathing. U-shaped nails were popular for lath. The loose attachment allowed mortar to key behind the lath.

Furring strips were used on this 1925 house to space the lath away from the wall. The space allowed mortar to squish behind the lath for a solid bond and good reinforcement. Too bad the furring and the lath rotted. The chimney next to this wall leaked real bad. Also, they used interior lath and the mortar was too thin.

Small wood blocks were sometimes used for furring metal lath. The wood blocks were a better method. The long area behind the furring strip didn't allow mortar to key, creating a long weak area. You can see this on old houses with long vertical cracks every 16".

Tying laps of the metal lath on this interior plaster installation. Laps are tied with tie wire, two ties in between each stud.

3 inch over laps.

The standard for the minimum overlap for metal lath is one inch, but I say, why be cheap? Go 3 inches. Note how the inside and outside corners are reinforced with strips. There is a pre-made material for this called cornerite, which is pre-bent strips of lath. Crack resistant work begins with good lathing.

More about lath in my chapter I wrote in the future here: