More Stucco Question(s)

Mr. Bullard your question and answer page looks great. I need to upgrade my ignorance with a few very basic stucco questions. I have contracted a three coat stucco job plus elastomeric painting to a young man (with 19 years experience and two or three work crews). I trust him and unlike some other supposed experts I've used he does not rely on BS to sell his product/service. There are however some questions that concern me. He admits to not knowing a definitive answer to a couple of them. Others I have talked to in the installation and supply end have conflicting opinions.

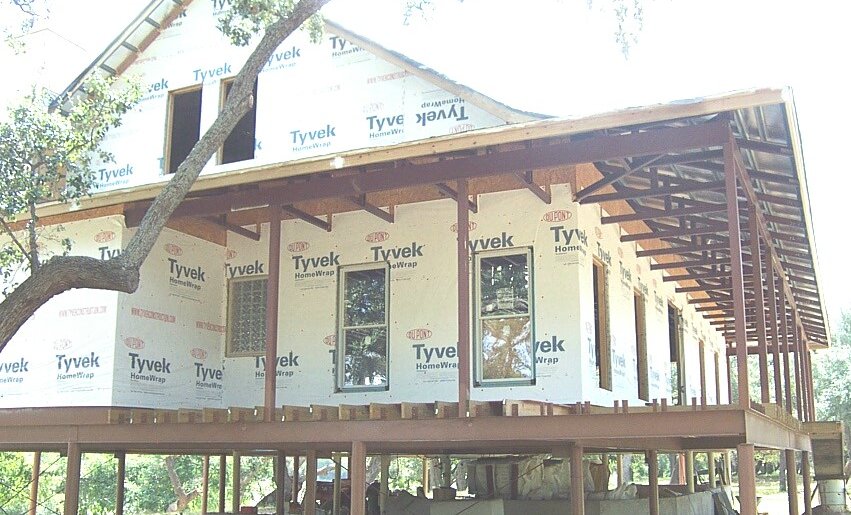

As background my home is under construction in central Texas. Annual rainfall 22 inches, humidity generally below 60% often less than 30% in summer months with temperatures in the nineties. The house is metal construction with 7/16 OSB attached to 20 gauge "hat channel". The OSB is presently covered with Tyvec Home Wrap (not stucco wrap). I am concerned whether I have the right barrier in the right place. Everyone says Tyvec is THE product but I'm unconvinced and my mudman says he's heard the same concerns expressed from Dupont's competitors and his contemporaries in this area of Texas. The majority of stucco is protected by porch all the way around. My main concern are the gables exposed to mighty hot sun and some rain - see picture.

If Tyvec works great in the northern climate it doesn't necessarily follow that it works the same in a hot arid climate where the cold is generally on the inside and the hot on the outside? It seems to me if Tyvec is a one-way barrier I'll have water vapor migrating out; only to be trapped between the Home Wrap and the elastomeric paint on the stucco. Because the outside temperature is warm it seems unlikely the trapped water vapor will readily condense to water and run down behind the stucco. If that's true I'll have a lot of water vapor in the stucco all the time. I'm of the opinion there really hasn't been enough time to observe Tyvec in the long haul when compared to stucco life. DOW and my mudman's contemporaries have convinced him to revert to paper for this geographic area

What is your opinion on water barriers in warm climates? Should I use something besides an elastomeric paint so the stucco can breath? I presume I need elastomeric because I have elected to NOT use expansion joints and I can't find a premix that passes the wife color test. I prefer to see natural stucco cracks rather than large man made ones. While steel will not eliminate movement I am betting my steel frame will minimize major cracking. The house frame is 14 and 16 gauge "C" channel not light gauge steel.

Second, two of the three bidders (including my guy) say that half inch casing resulting in about 5/8 finished stucco is the norm in this area. One guy says three quarter casing and 7/8 of an inch total is better. While I have little confidence in the last guy, common sense and more than a few years looking at houses convinces me 3/4 should be better. Your opinion? Portland will have fiber in it.

Third, how much does the weight of the mesh effect quality/durability? My guy normally uses 2.5 lb I believe, and I see code requirements on the net for 3.4. Should I ask for a heavier weight?

Thanks for taking the time.

Tar paper is preferable over tyvek. Now you have tyvek on, and the windows wrapped, you can put a layer of tar paper over top. I used to tear off tyvek and people would get mad. The Stucco Manufacturers Association in California recommends tar paper over tyvek. A standard in California since the late 1990's is two layers of paper. A layer of tar paper over the tyvek would be an equivalent. To clarify about paper, in California they use what is called grade D building paper, which is unknown here. What we use here is 15# felt paper, which is the equivalent of grade D paper. These are asphalt (petroleum) impregnated papers that will pass a water test on how long it takes water to soak through. I don't know which paper you have in Texas, but they have the same results.

Expansion joints (or control joints) are ugly and I don't use them unless someone really insists. I see horizontal joints everywhere these days, and not only are they ugly, and usually leak, but they stop the downward drainage of water out of the stucco, which is the largest cause of expansion anyway. Since we mainly do historic type work, my argument is that expansions weren't used on old houses, and the old houses are in good shape. Metal joints weren't invented until the 1950's.

I like breathable over elastomeric, but this is a constant debate. I would go with the wife test first. You may have cracks in stucco whatever you do, particularly on wood framing. With the heavy metal studs and the hat channel cross furring, you probably won't have any cracks anyway, at least only very few.

I would go with the 3/4" guy, and get rid of bachelor number 1 and bachelor number 2. All we do is 3/4" thickness. I may do some of the thin one coat stucco one day, but I doubt it. The standard for years and years for stucco has been 3/4", with good reason. A lot of our repair work on old houses is due to the original mortar being too thin. We work in neighborhoods where the houses with thin mortar are in bad shape, but the old houses with 3/4"-1 inch are in good shape. There is no doubt the small additional thickness stops a lot of water infiltration. Not to mention, thickness equals strength. For example, look at sheetrock. 5/8" sheetrock is a lot tougher to break than 1/2". Only 1/8" is a huge difference in strength and quality.

2.5 metal lath should be fine for side walls, that is what we use. You want 3.4 for ceilings. The heavier lath will prevent the scratch coat from sagging.

We had to use 3.4 for everything on government work. What these numbers mean is 2.5 lath weighs 2.5 pounds per square yard, and 3.4 means 3.4 pounds per square yard. I can identify the difference from experience. The way to tell the difference is there is a metal tag on each bundle of lath identifying the weight. When I did Washington, DC government work, the inspectors would take some of the lath and weigh it. They didn't trust contractors not to swap the tags.

Thanks so much for visiting my site.