Lath for insulated concrete forms

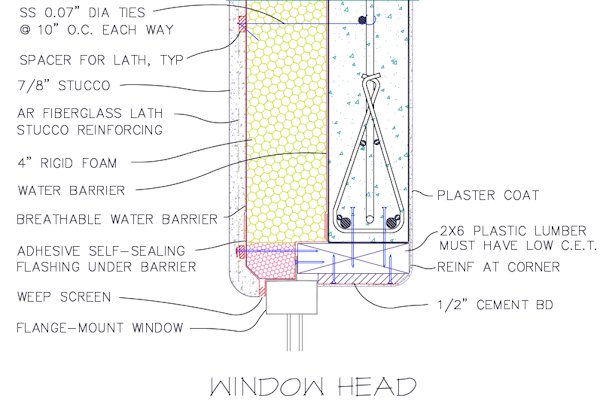

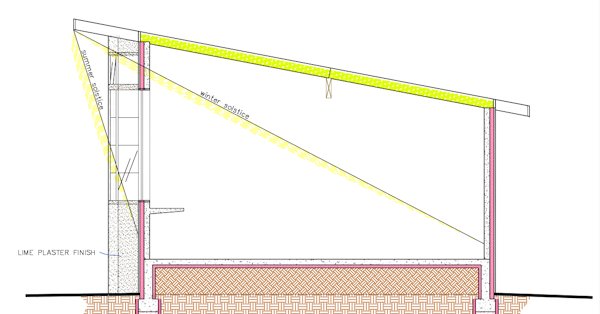

Dear Reggie: We have figured out a way to pump concrete to cast walls in place without any forms. Long story. This makes it easier to build thermally beneficial homes: concrete inside, foam outside. Ideally no vegetable matter anywhere. A few details and images are attached. The reason for writing you is that this uses stucco over the 4" +/- foam. It ties to the concrete with SS wires that are previously cast in place. Before stucco, we trowel on a breathable waterproofing - which is actually leftover silicone from a solar panel manufacturer that went broke. That's right, even a photo above. The first test project has had no stucco problems, but it is very small. Fiberglass lath - we are right next to the Pacific. Lime + white cement. The first real (20'x40') building is now underway, and I am very interested in whatever you may think about this approach to stucco cladding will hold up. How we tie the lath into place is definitely not the easiest - in fact it is the most laborious / least efficient aspect of the construction method. Of course EIFS would be so easy, but given the foam substrate, I prefer cladding that is not extremely flammable. Thank you very much!

A view of the window head detail showing the tie wire cast in place for the metal lath

A view of the wire ties through the spacers.

What a great design !

Casting the tie wire and spacers in the concrete was an

excellent idea.

One idea I had is to twist the wire around a nail

or a screw. and tighten up the lath by twisting the nail.

Once the mortar sets up the nail will never untwist.

I have some doubt about fiberglass (plastic)

lath. Bear in mind, this is plastic. Glass fibers are a hazardous

material. My doubt is if the openings in the lath are big enough

for mortar to squish through easily, not pinning the lath

to your substrate.

I have seen plastic lath that looks like

EIFS mesh advertised for

stucco applications lesss than 3/8", which we don't

do. This may be fine for one-coat stucco, but our standard

thickness is 3/4".

Plastic lath like ultra lath and other plastic accessories

may be good for warm climates like Florida, but don't stand

up against cold weather like we have in Virginia.

In this job the ultra lath had deteriorated to the point

it ripped easily. The reason the stucco was failing

is the mortar didn't key into the lath.

On this 7 year old addition, you could shake the

stucco with one hand. At least it was easy to tear off.

Every time I have seen ultra-lath put on floors, it was

put on upside down. At least the force of gravity

holds the mortar to the floor, but the lath offers no reinforcement value.

I have seen people put on EIFS cloth and EIFS finish on ICF

and it makes me want to puke. Why would anyone want to cheapen their

house after such an effort I'll never know.

This is a very well planned and executed project.

I am sure you will have a great product when finished.

Thanks for writing. I plan to publish this in the next few days

Outbuilding concrete pour showing 4 inch foam forms.

Passive solar design.